GI Scaffolding Steel Pipe

GI Scaffolding Steel Pipe

1.Size:

Outer diameter: 38mm,42mm,48.3mm-48.6mm

Thickness: 1.5-4.75mm

Length: 1-16m or customized

2.Material : Q235 , Q345, GRA, GRB, SS400 and STK400/500,S235,S355

| ElementsMaterial | Chemical Composition% | Mechanical Property | ||||||

| C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation (%) |

|

| Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.30 | >195 | 315-430 | 32-33 |

| Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.30 | >215 | 335-450 | 26-31 |

| Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.30 | >235 | 375-500 | 24-26 |

| Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 | >345 | 470-630 | 21-22 |

3.Standard : GB/T13793-2008 / BS1139/EN39

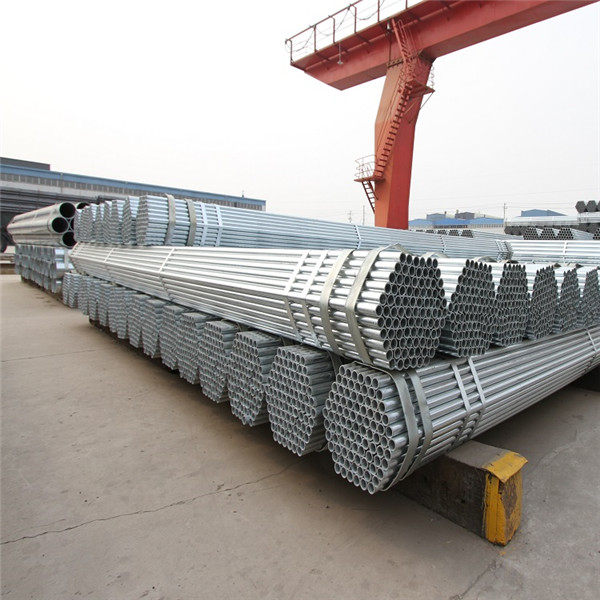

4.Package for GI Scaffolding Steel Pipe :

4.1.In bundles

4.2.Oiled and waterproof packaging in outside

4.3.According to your requirements

5.Delivery lead time of GI Scaffolding Steel Pipe: 7-15 days after your deposit or relevant L/C at sight

6.Surface: hot-dip galvanized, black, anti-rust oil, coated, electro galvanized

7.Application: scaffolding systems

1) Outer Diameter : 6-508mm

2) Wall thickness :0.4-25mm

3) Length : Max. 16 meters

4) Standard :GB, ANSI,ASME,ASTM, JIS,DIN,BS,EN

5) Steel Grade :

Q195 → Grade A, SS330,SPHC, S185

Q215 → Grade B,CS Type B,SS330, SPHC

Q235 → Grade B,SS400,S235JR,S235JO,S235J2

Q345 → SS500,ST52

6) Packaging : Plastic Cap, In bundle.

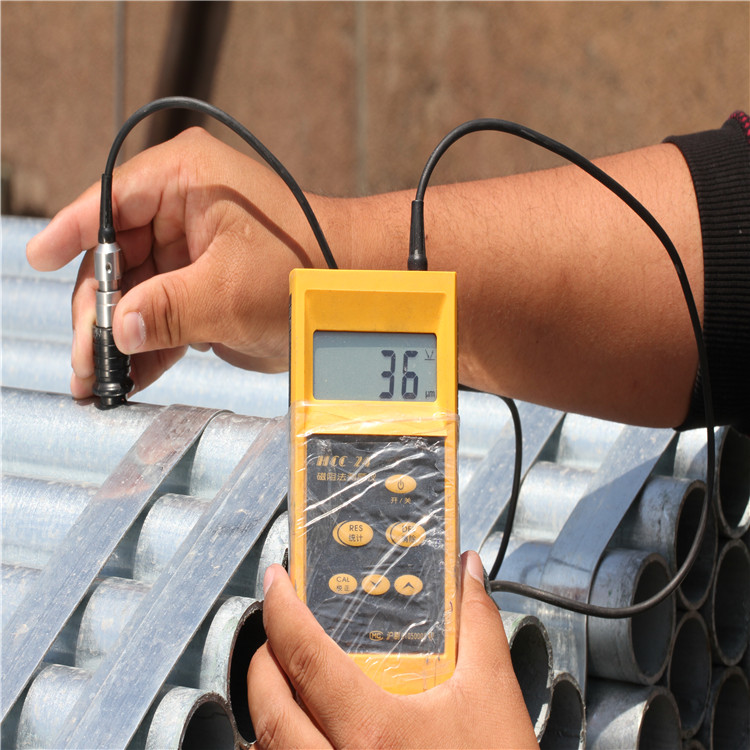

7) Zinc coating :40-600g Per M 2

8)Applicationspetroleum, power,gas metallurgy, papermaking, chemical, medical equipment, aviation, boiler heat, exchanger,shipbuilding, construction, etc.

| O.D | O.D tolerance | W.T | Thickness Tolerance |

| 6-508MM | ±0.03 | 0.4-25MM | ±0.02 |

| Length | 1-16M , according to customers’ requirements | ||

| Zinc coating | 40–600g/m2 | ||

| International Standard | ISO 9001;2000 | ||

| Standard | GB, ANSI,ASME,ASTM, JIS,DIN,BS,EN | ||

| Material | Q195 → Grade A, SS330,SPHC, S185Q215 → Grade B,CS Type B,SS330, SPHCQ235 → Grade B,SS400,S235JR,S235JO,S235J2Q345 → SS500,ST52 | ||

| Product Category : | Metallurgy, Mineral & Energy | ||

| Technique: | Welded, cold drawn, hot rolled, cold rolled | ||

| Packing | hexagonal water proof packing, packed by steel bands each bundle, with PVC caps, with two nylon slings for lifting | ||

| Usage | 1.For low pressure liquid delivery such as water , gas and oil2.For construction , e.g building greenhouse | ||

| Main market: | Middle east, Africa, North and South America, East and West Europe, South and southeast Asia,Australia | ||

| Place of Origin | China | ||

| HS code: | 7306309000 | ||

| Productivity | 6000 Ton per Month | ||

| Processing technology available: | Threading , coupling and with plastic caps protected | ||

| Remarks | 1) Payment term :T/T2) Trade Terms : FOB / CFR /CIF | ||